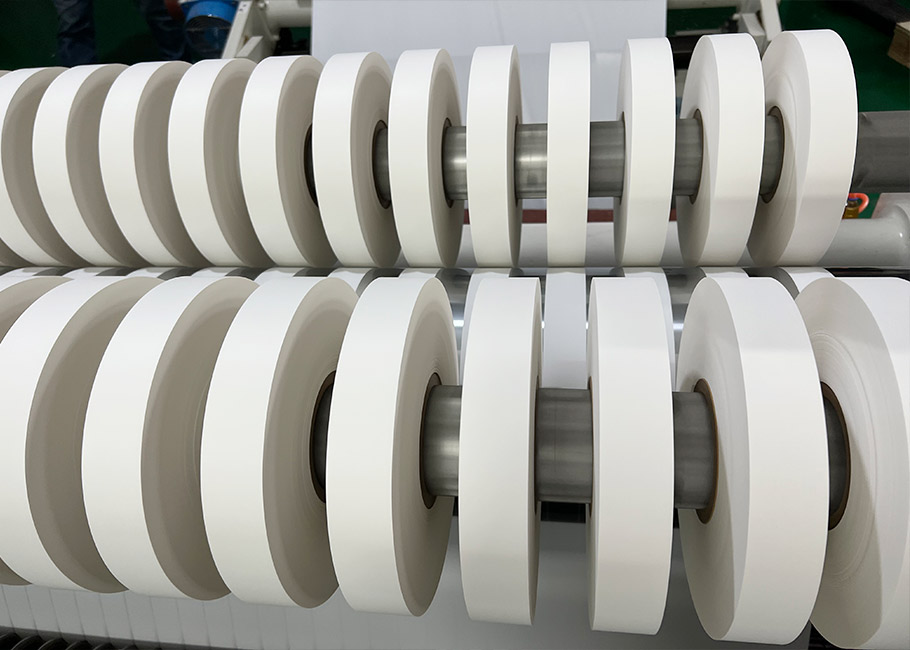

White Kraft Wrapping Paper Roll

- Product Information

White Kraft Wrapping Paper is a type of wrapping paper made mainly of Kraft Paper. It is usually white in color and is usually found in large rolls. The paper is tough, has a tight fiber structure, good flexibility and a certain thickness. It can provide effective isolation and protection for products and is one of the commonly used materials for product packaging in many industries.

Parameters:

| Material: | Kraft Paper |

| Size: | Customizable Material Width And Thickness According To Customer Requirements |

| OEM: | OEM/ODM Available |

| Packaging: | Carton |

Features:

Excellent tensile strength: The tensile strength of White Kraft Wrapping Paper can reach about 1200 kg/cm2. This is because it is made of high-quality wood pulp, and the fibers are tightly bound. When subjected to tension, the fibers can support each other and are not easy to break. Even if heavy items are packaged, they can maintain their integrity and provide stable packaging for the product.

Moderate and uniform thickness: The thickness is usually around 0.15 mm, and the thickness uniformity is excellent. The paper thickness deviation is very small in the entire paper roll, which enables stable buffering and protection effects to be provided during the packaging process, and the packaging quality will not be affected by local excessive thickness or thinness, ensuring that the product is evenly protected during transportation and storage.

Good flexibility: It can be bent to 180 degrees without breaking. Its flexibility comes from the flexibility of the paper fiber and the processing technology of the paper, which enables it to be flexibly wrapped according to the shape of the object, closely fit the product contour, reduce packaging gaps, better protect the product, and facilitate packaging operations and improve packaging efficiency.

Good temperature resistance: The performance remains stable within the temperature range of -30 degrees Celsius to 100 degrees Celsius. Whether in high or low temperature environments, the paper will not deform or crack, and can adapt to product packaging needs in different temperature environments, ensuring that the product can be properly protected under various temperature conditions.

Moderate water absorption: The water absorption rate is about 10%. When encountering a small amount of water, it can absorb it appropriately to prevent the packaging surface from being too wet and affecting the wrapping effect, but it will not absorb too much water to cause the paper strength to decrease. It can adapt to packaging operations in general humid environments and ensure the integrity of the packaging.

Application:

Electroplating industry: During the electroplating process, White Kraft Wrapping Paper is cut into suitable sizes and used to wrap metal parts to be electroplated. Its good isolation performance can prevent metal parts from being contaminated by the outside world before electroplating, and can also prevent parts from scratching each other during the electroplating process, ensuring the quality of electroplating and improving the electroplating yield rate. For example, when electroplating some small metal parts, wrapping them with it can effectively reduce defects.

Stamping industry: In the stamping workshop, metal sheets are first wrapped with White Kraft Wrapping Paper, and then stamped. With the flexibility and cushioning of paper, it can reduce the direct collision between metal sheets and equipment, reduce the risk of scratches, dents and other defects on the surface of the sheet, effectively protect the surface finish of the metal sheet, and improve product quality.

Electronic hardware industry: Electronic hardware products are precise, and they are individually packaged with White Kraft Wrapping Paper, which can effectively isolate the products from the external environment, prevent static electricity, dust and other damage to the products, and reduce collisions and friction between products during transportation and storage, ensuring that product performance is not affected and extending product life.

Printing and packaging industry: When packaging printed products such as books and albums, wrapping the finished products with White Kraft Wrapping Paper can prevent the printed products from being squeezed and wrinkled during transportation, avoid the printing ink from being rubbed, ensure the appearance quality of the printed products, and keep the products in good condition during circulation.

Other general industrial product packaging: For ordinary industrial parts, small mechanical products, etc., White Kraft Wrapping Paper is an ideal packaging material. It can quickly package the products and form a protective layer, which is convenient for the handling, storage and transportation of the products, reduces the damage rate of the products during circulation, and improves logistics efficiency.

Maintenance:

Storage environment humidity control: White Kraft Wrapping Paper should be stored in an environment with a relative humidity of 40% to 60%. If the humidity is too high, the paper will easily absorb moisture, become soft and collapse, and its strength will decrease; if the humidity is too low, the paper will become brittle and hard. It is necessary to regularly monitor the storage environment humidity with a hygrometer, adjust the humidity through a dehumidifier or humidifier, maintain good physical properties of the paper, and ensure that it can perform at its best when used.

Storage environment temperature management: The storage environment temperature should be controlled between 15 degrees Celsius and 25 degrees Celsius. Too high temperature will accelerate the aging of paper, reduce strength and flexibility; too low temperature will make the paper fragile. Paper rolls should be stored in a warehouse with temperature control function, avoid direct sunlight, away from heat and cold sources, and stabilize the temperature to maintain paper quality and extend service life.

Avoid pollution: During storage and use, prevent paper from contacting pollutants such as oil and chemicals. Oil will destroy the fiber structure of paper, affect strength and isolation performance; chemicals may react with paper, causing discoloration, damage, and even the production of harmful gases. During handling and packaging operations, staff should wear clean gloves and use cleaning tools to ensure a clean packaging environment and paper quality.

Reasonable stacking: When storing multiple White Kraft Wrapping Paper rolls, the number of stacking layers should not exceed 5, otherwise it will cause excessive pressure on the bottom roll, causing the roll to deform, the paper to loosen or indent. It is best to use shelves when stacking, and place partitions between each layer to disperse the pressure, ensure the integrity of the paper roll, and facilitate subsequent use.

Regular inspection: Regularly inspect the stored White Kraft Wrapping Paper to check whether the paper is damp, moldy, or moth-eaten. The inspection cycle is generally once a week. If problems are found, they should be dealt with in a timely manner. For example, paper that is less damp can be dried in the sun, and paper that is severely moldy needs to be isolated and professionally treated for mold removal. For paper that is moth-eaten, the source of the insects should be found and the insects should be eliminated to ensure the quality of the paper and extend its service life.

FAQs:

Is it possible to alter the dimensions of the White Kraft Wrapping Paper?

The size of White Kraft Wrapping Paper can be customized. The specific widths, lengths, and thicknesses of the material can be tailored to meet client specifications. You may send in your size requirements, and we will develop a quotation based on your needs.

Is White Kraft Wrapping Paper suitable for heavy-duty industrial applications?

Yes, the White Kraft Wrapping Paper has a high tensile strength and ts tearing strength makes it best suited for heavy industrial applications. It is extensively used for these applications in the field of electroplating, stamping, electronics, and hardware packaging and it helps protect the various components while in transit and other processing stages.

How should I store White Kraft Wrapping Paper to maintain its quality?

White Kraft Wrapping Paper should be kept in a clean and dry environment free from moisture and direct sunlight. They should also be kept away from vertical surfaces to prevent rolling which causes the paper to crease.