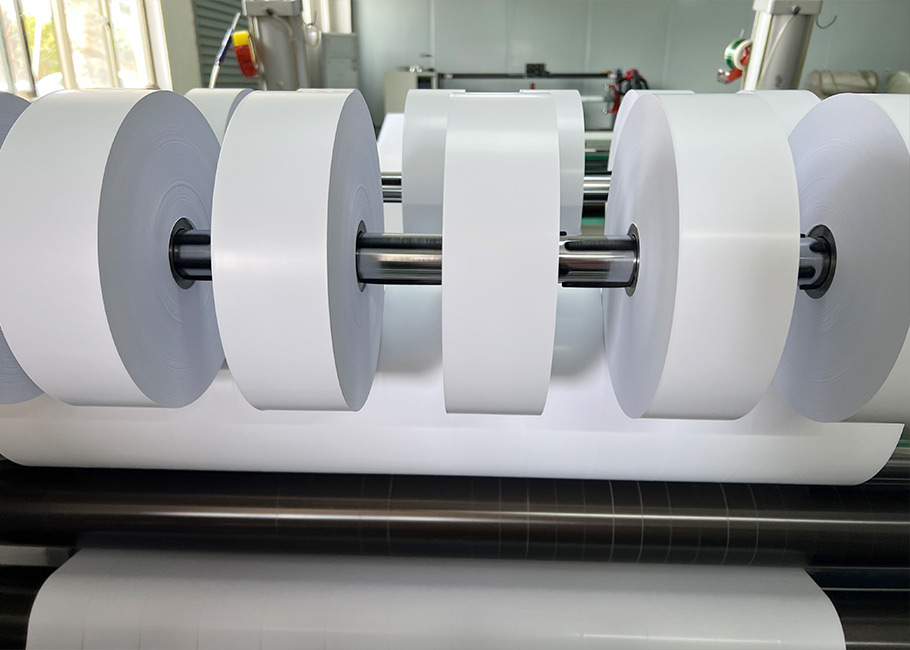

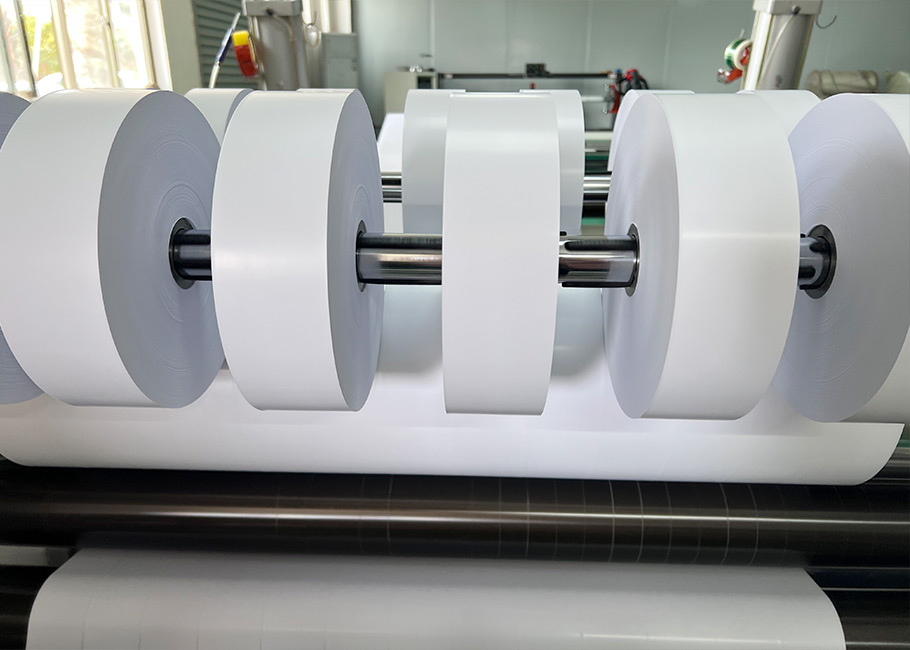

White PE Laminated Paper

- Product Information

PE Laminated Paper is a material that combines paper and polyethylene (PE) through a specific process. It uses paper as the base material and utilizes the characteristics of polyethylene to give the paper better physical and chemical properties. It is an innovative product that improves paper performance and is often used in industrial fields that have high requirements for material performance. It can provide isolation and protection for various products and has a wide range of applications in many industries.

Parameters:

| Material: | Paper And PE |

| Size: | Customizable Material Width And Thickness According To Customer Requirements |

| OEM: | OEM/ODM Available |

| Packaging: | Carton |

| Factory Nature: | China Manufacturers Suppliers Factory |

Features:

Excellent tensile performance: PE Laminated Paper has extremely high tensile strength. After professional testing, its longitudinal tensile strength can reach 30-50 MPa, and its transverse tensile strength is also about 20-30 MPa. This means that when subjected to external force pulling, whether along the length or width of the paper, it can show strong toughness and is not prone to breakage. It can effectively resist the tensile stress that may be encountered in transportation, processing and other links, and provide reliable physical support for product packaging and protection.

Excellent strength performance: The material has a high puncture resistance. Test data shows that its puncture resistance can reach 100-200 N. In the face of the top puncture of sharp objects, it can withstand greater force without being easily punctured, ensuring that the product will not be damaged by accidental collision or extrusion in the packaging state, ensuring the integrity of the product during circulation.

Excellent waterproof performance: In the waterproof performance test, PE Laminated Paper can completely block the penetration of water. After 72 hours of water immersion test, its back can still remain dry and free of water marks. This is because the polyethylene layer provides a dense waterproof barrier for the paper, and moisture cannot penetrate this barrier to reach the inside of the paper, thereby effectively preventing the product from getting damp and deteriorating. It is particularly suitable for packaging products in humid environments or that need to be exposed to moisture.

Significant moisture-proof effect: In a high humidity environment with a relative humidity of 90%, PE Laminated Paper still has excellent moisture-proof performance. It can control the moisture absorption rate of paper at an extremely low level, usually not exceeding 5%, which is much lower than the moisture absorption rate of ordinary paper in the same environment. This enables it to maintain its physical and chemical properties for a long time, and will not cause paper deformation, mold and other problems due to changes in environmental humidity, providing a strong guarantee for product quality.

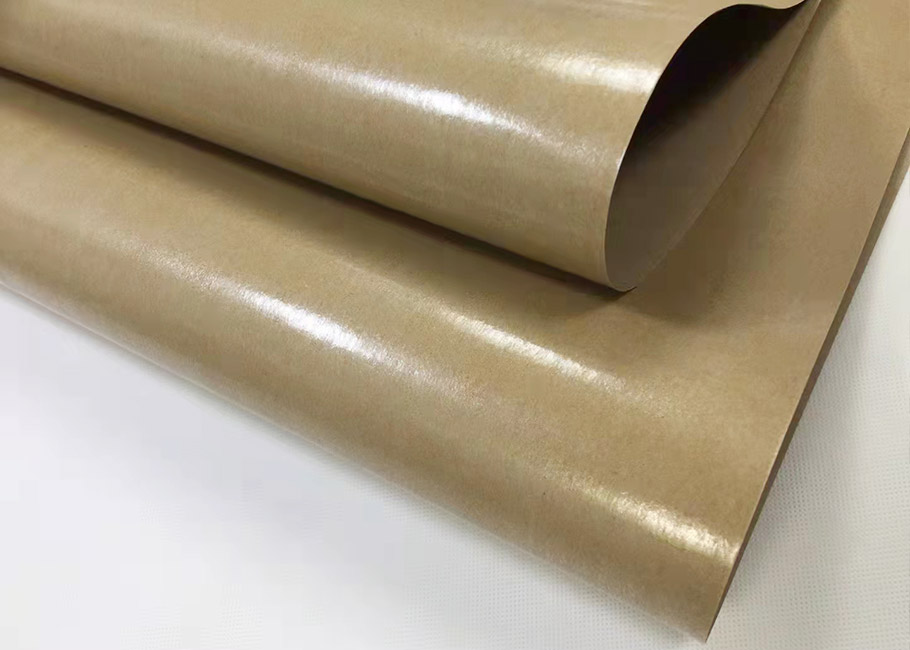

Smooth and flat surface: The surface smoothness of PE Laminated Paper is extremely high, and its average surface roughness can reach less than 1.5 μm. This smooth and flat surface is not only conducive to printing, writing and other operations, and can present a clearer and more beautiful graphic effect, but also reduces friction resistance when in contact with other materials or products, which is convenient for product processing and use, and also helps to improve the appearance of the product.

Application:

food packaging industry: PE Laminated Paper is widely used in the field of food packaging. For example, it is used to make paper cups, paper bowls, disposable tableware, etc. The waterproof performance of its PE coating surface enables these products to maintain shape and strength when containing liquids without leakage. When packaging fast food such as sandwiches, hamburgers, and French fries, its moisture-proof and oil-proof properties can ensure the freshness and taste of the food, prevent the packaging materials from being affected by moisture or oil penetration and affect the food quality, and at the same time block external pollutants to ensure the hygiene and safety of the food.

Medical packaging industry: In the medical field, PE Laminated Paper can be used as sterile packaging materials for packaging surgical instruments, medical equipment, etc. Its good moisture-proof and waterproof properties can provide a sterile barrier for medical supplies, prevent the invasion and contamination of microorganisms, ensure the sterility of medical supplies during storage and transportation, and ensure medical safety. In addition, it can also be used to make the lining of drug packaging such as medicine bottles and medicine boxes to protect the drugs from environmental factors and maintain the quality stability and effectiveness of the drugs.

Printing industry: PE Laminated Paper is widely used in the printing industry because of its smooth surface and high-quality printing effect. It can be used to print business cards, brochures, posters and other business printed materials with bright colors and clear patterns to enhance the visual effect of the brand. At the same time, its waterproof and moisture-proof properties ensure the quality stability of printed materials in different environments and extend the service life. In addition, when publishing high-quality reading materials such as magazines and picture albums, the use of PE Laminated Paper can improve the wear resistance and folding resistance of paper, making the printed materials more durable and ornamental.

Building decoration industry: PE Laminated Paper plays an important role in the packaging and protection of building decoration materials. For example, it is used for packaging linings of building materials such as tiles and stones to prevent the materials from being scratched and collided during transportation and storage, thereby damaging the surface. At the same time, its waterproof and moisture-proof properties can protect the materials from the influence of humid environments and avoid problems such as discoloration and cracking of the materials. In addition, at the construction site, PE Laminated Paper can also be used to build temporary protective barriers or work surfaces to provide convenience and protection for the construction process.

Electronic hardware industry: Electronic hardware products usually have higher requirements for packaging materials, and PE Laminated Paper is an ideal choice. It can isolate electronic hardware products from the external environment and prevent the products from being contaminated by water vapor, dust, etc. At the same time, its good strength and tensile properties can withstand the stacking pressure of products during transportation and storage, protecting the products from damage. In addition, in the production process of electronic hardware products, PE Laminated Paper can also be used to make various temporary partitions, pallets, etc., to facilitate the handling and assembly of products and improve the management efficiency of the production site.

Maintenance:

Storage environment control: PE Laminated Paper should be stored in a dry, ventilated and clean warehouse. The temperature should be controlled at 20-25℃ and the humidity should be maintained at 40%-60%. Too high temperature may soften and deform the polyethylene layer, affecting the overall performance of the material; while excessive humidity can easily cause the paper to get damp, thereby reducing its strength and moisture resistance. At the same time, the warehouse should avoid direct sunlight and stay away from heat sources and corrosive substances such as acids and alkalis to prevent the material from aging or performance degradation.

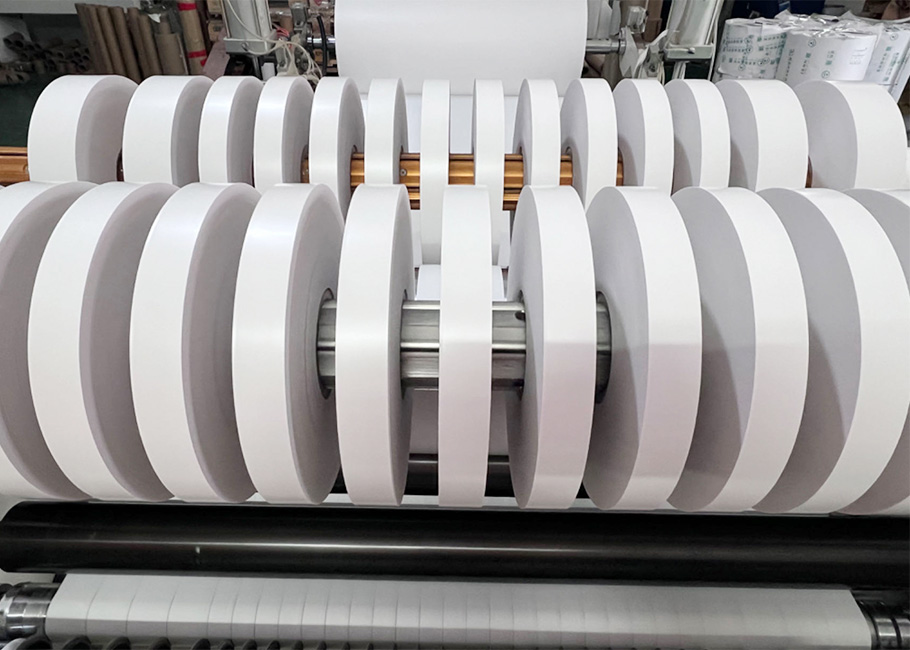

Precautions for handling and loading and unloading: When handling and loading and unloading PE Laminated Paper, it should be handled with care to avoid violent collisions and falls. It is best to use padded handling tools to prevent scratches or creases on the surface of the material. If it is a roll of material, it should be placed upright and a wooden board or pallet should be placed at the bottom to prevent the material from directly contacting the ground and getting damp or contaminated. At the same time, the handling personnel should wear gloves to prevent sweat and stains on the hands from contaminating the surface of the material, affecting its quality and use effect.

Daily use and maintenance: During daily use, avoid stacking heavy or sharp objects on the surface of PE Laminated Paper to avoid scratching the surface of the material or causing local indentations, which will affect its appearance and performance. If the surface of the material is stained with dust or stains, it should be wiped gently with a clean soft cloth in time. For stubborn stains, an appropriate amount of neutral detergent can be used for cleaning, but be careful to avoid detergent residue to avoid corrosion to the material. During use, if the material is found to have slight damage or scratches, it should be repaired or replaced in time to prevent the damage area from expanding and affecting its use function.

Regular inspection and maintenance: Regularly inspect the PE Laminated Paper stored and used, including whether the appearance of the material is intact, whether there are signs of moisture or mold, and whether the strength and performance have changed. The inspection cycle can be determined according to the actual use situation. It is generally recommended to check once every 3 months. If problems are found, appropriate treatment measures should be taken in time, such as drying, repairing or replacement, to ensure that the material is always in good condition and can meet the use requirements.

Avoid contact with chemicals: When using and storing PE Laminated Paper, try to avoid contact with organic solvents, strong acids and alkalis and other chemicals. If you must use related chemicals, you should test a small area in advance to make sure that it has no adverse effects on the material before using it with caution. Once the material accidentally comes into contact with chemicals, it should be immediately rinsed with plenty of water and handled accordingly according to the actual situation, such as cleaning, drying, etc., to reduce the damage to the material by chemicals and extend its service life.

FAQs:

What is PE Laminated Paper made of?

PE Laminated Paper is made by laminating a layer of Polyethylene (PE) onto high-quality paper. Such combinations give better moisture, better strength, and better surface finish.

Is it possible to get a customized PE Laminated Paper in the desired size?

Yes, we offer full customization of PE Laminated Paper to meet your specific requirements. You can adjust the width and thickness of the paper to suit the scope of its utilization.

How should I keep PE Laminated Paper in good condition?

In order to protect the quality and the properties of PE Laminated Paper, it must be stored at controlled temperatures, in clean, dry conditions avoiding direct exposure to sun and humidity. Paper rolls should be kept on a flat surface in order to prevent bends and creases in the paper.