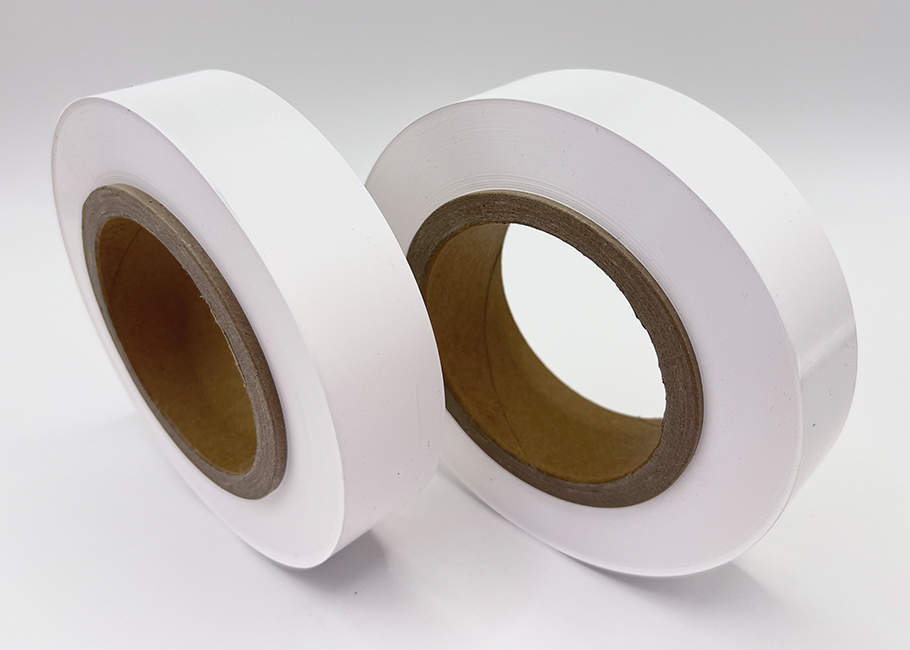

Li Ion Battery Separator

- Product Information

Li Ion Battery Separator is one of the key internal components of lithium-ion batteries. In the structure of lithium-ion batteries, the separator is between the positive and negative electrodes, and its main function is to isolate the positive and negative electrodes and prevent the two electrodes from directly contacting each other and causing a short circuit. At the same time, it also allows lithium ions to freely shuttle between the positive and negative electrodes during the battery charging and discharging process, thereby ensuring the normal charge and discharge cycle of the battery.

Parameters:

| Material: | Polypropylene (PP) And Polyethylene (PE) |

| Dimensions: | Customizable Material Width And Thickness According To Customer Requirements |

| OEM: | OEM/ODM Available |

| Packaging: | Carton (should Not Be Subjected To Impact) |

| Factory Nature: | China Manufacturers Suppliers Factory |

Features:

Electronic insulation: Li Ion Battery Separators have excellent electronic insulation properties, and their insulation resistance can reach more than 10¹⁶ Ω・cm. This high insulation ensures effective isolation between the positive and negative electrodes, preventing short circuits caused by direct conduction of electrons, thereby ensuring the safe operation of the battery.

Aperture and porosity: The pore size of the separator is usually between 10 nm and 500 nm, and the porosity is generally between 40% and 74%. For example, the average pore size of some high-performance separators is about 425 nm, and the porosity reaches 74%. This pore structure design allows efficient transmission of lithium ions and can prevent direct passage of electrons to a certain extent, optimizing the ionic conductivity and electrochemical performance of the battery.

Puncture strength: The puncture strength of the separator is relatively high, usually reaching more than 0.5 N/μm. This feature enables it to resist local stress generated by the volume expansion of electrode materials inside the battery, prevent the separator from being punctured, and thus avoid safety hazards caused by direct contact between the positive and negative electrodes.

Tensile strength: The tensile strength of the separator in the longitudinal and transverse directions can reach 30 MPa and 20 MPa, respectively. This high strength helps the diaphragm maintain the stability of size and shape under various mechanical stresses during battery manufacturing, assembly and use, ensuring the smoothness of lithium ion transmission channels and extending the service life of the battery.

Chemical stability: The diaphragm has excellent chemical stability in common carbonate electrolytes and can maintain its physical and chemical properties for a long time during the battery's charge and discharge cycle. For example, at 60°C, the diaphragm can operate stably in the electrolyte for more than 1,000 hours, ensuring the long-term stability of battery performance.

Application:

New energy vehicles: As a key component of new energy vehicle power batteries, the performance of the separator directly affects the vehicle's cruising range, acceleration performance and safety performance. High-performance separators can improve the energy density and cycle life of the battery, allowing the vehicle to operate stably under high energy output conditions, while preventing internal short circuits in the battery in unexpected situations such as collisions, ensuring the safety of drivers and passengers.

Electric vehicles: After optimizing parameters such as the pore size and porosity of the separator, the charging and discharging efficiency and cycle life of the battery can be significantly improved. This enables the battery pack of electric vehicles to maintain good performance in frequent charging and discharging cycles, reducing maintenance costs and battery replacement frequency, and promoting the widespread application of electric vehicles.

Mobile devices: In mobile devices such as smartphones and tablets, the thin design and high porosity characteristics of the separator enable the battery to achieve higher energy density in a limited space and extend the use time of the device. At the same time, the high chemical stability and mechanical strength of the separator ensure the safety and reliability of the battery in daily use.

Energy storage system: The separator plays a vital role in the energy storage system. Its high ionic conductivity and low electrolyte resistance can improve the energy conversion efficiency and response speed of the energy storage system. High-quality diaphragms can ensure the stability of energy storage systems in long-term operation and adapt to various application scenarios such as power grid peak regulation and emergency power supply.

Aerospace and defense fields: The high safety and reliability of diaphragms make them important applications in the aerospace and defense fields. Specially modified diaphragms can work stably in special environments such as extreme temperatures and high vibrations, providing reliable energy guarantees for satellites, drones and other equipment to ensure their normal operation.

Maintenance:

Storage environment control: The diaphragm should be stored in an environment with a temperature of 20℃-25℃ and a humidity of less than 40%. Excessive humidity will cause the diaphragm to absorb moisture and affect its performance; temperature fluctuations may cause the diaphragm material to age or deform. Strict control of the storage environment can ensure that the diaphragm is in optimal condition before use.

Avoid mechanical damage: During transportation, handling and assembly, special tools should be used to handle the diaphragm with care to avoid mechanical damage such as squeezing, scratching or folding. Mechanical damage will destroy the pore structure of the diaphragm and increase the risk of internal short circuits in the battery, thereby affecting the performance and safety of the battery.

Cleaning and maintenance: Regularly use deionized water or neutral cleaning solution, and use a soft brush or dust-free cloth to gently wipe the surface of the diaphragm to remove dust and dirt. Keeping the diaphragm surface clean helps prevent battery side reactions caused by impurities and extend the battery life.

Prevent chemical contamination: During battery manufacturing and use, the diaphragm must be strictly prevented from contacting chemicals such as oils, acid and alkali solutions. These substances may corrode the diaphragm material, change its chemical structure and physical properties, and thus affect the normal operation of the battery.

Regular performance testing: Establish a complete performance testing system for diaphragms, and regularly test the key performance indicators of the diaphragms in stock, such as pore size, porosity, and tensile strength. For diaphragms installed in batteries, indirectly evaluate the use of diaphragms by monitoring battery charge and discharge performance, internal resistance changes and other parameters. Once performance abnormalities are found, timely measures should be taken to ensure safe and reliable operation of the battery.

FAQs:

What materials are used to manufacture your Li Ion Battery Separators?

Our Li Ion Battery Separators are developed from Polypropylene (PP) and Polyethylene (PE) that are highly resistant with enhanced electrical meltdowns, tensile loads and excellent burst strength.

Can the size and thickness of the Li Ion Battery Separators be customized?

Yes, our Li Ion Battery Separators thickness and width can be customized totally as per the demands and expectations of the customer.

How are the Li Ion Battery Separators prepared for transportation?

Li Ion Battery Separators are packed in cartons with the utmost care since it is important that the delivery make it without ruining the product. All necessary precautions are taken in handling the cartons so that the separators do not get broken during shifting.