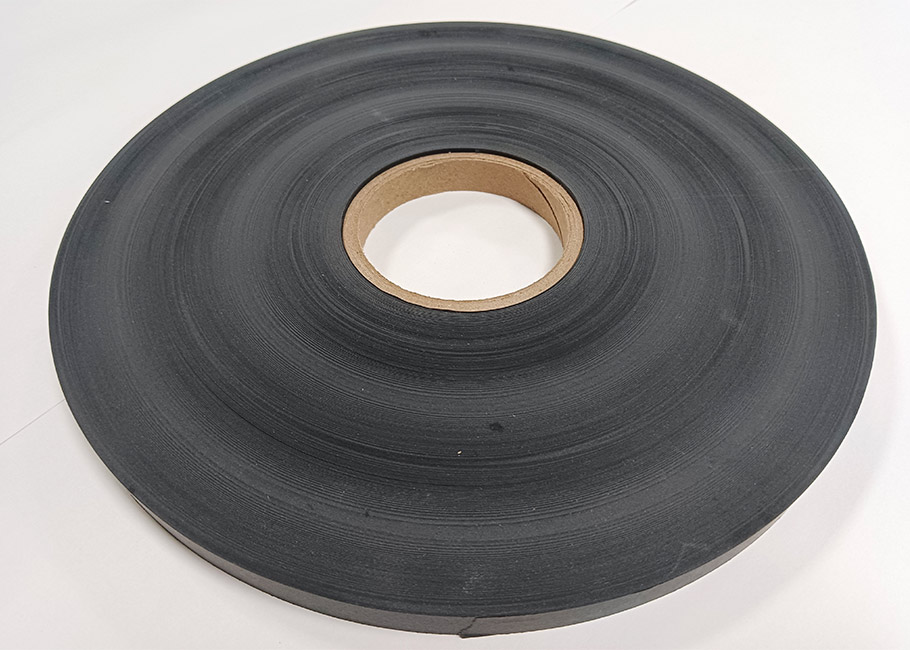

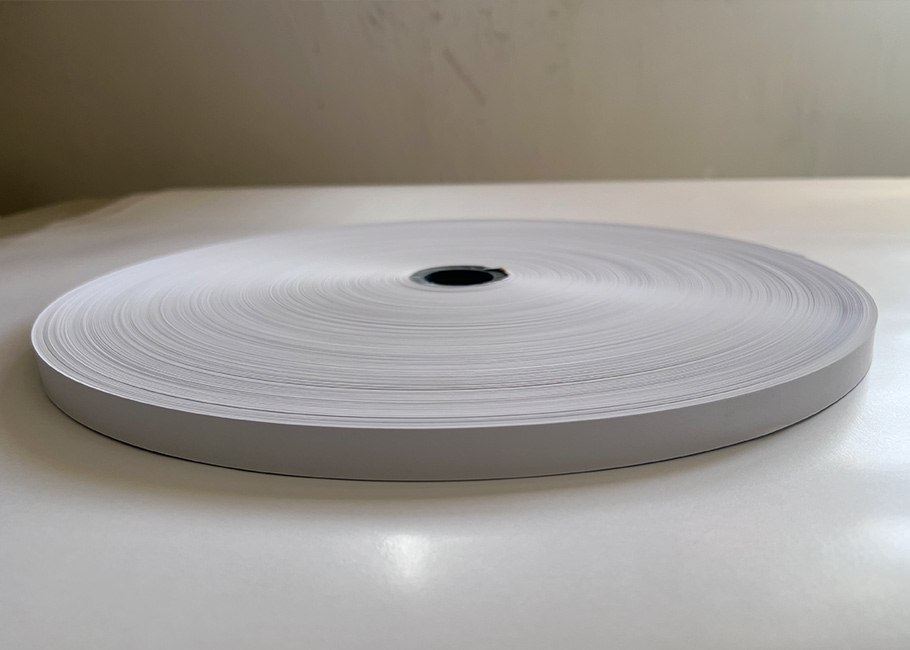

Double Offset Paper Roll

- Product Information

Double offset paper is a paper made of chemical wood pulp, usually printed by lithographic printing. Its main component is plant fiber, which undergoes a series of complex processing steps, including pulping, papermaking, coating, etc., to finally form a paper material with a certain thickness and strength.

Parameters:

| Material: | Offset Paper |

| Size: | Material Width And Thickness Can Be Customized According To Customer Requirements |

| OEM: | OEM/ODM Available |

| Packaging: | Paper Packaging |

Features:

Physical properties: The thickness of Double Offset Paper is generally between 0.08-0.15 mm, and the gram weight is usually 70-120 g/m2. It has high tensile strength, with a transverse tensile index of more than 45 Nm/g and a longitudinal tensile index of more than 55 Nm/g. It can withstand a certain amount of tension and pressure and is not easy to break during use. At the same time, it has good flexibility and is not easy to crack when folded, which is convenient for various folding processes.

Chemical properties: The pH value of offset paper is generally between 7-8, which is weakly alkaline and has good chemical stability. Under normal use and storage conditions, it is not easy to discolor or yellow, which can ensure that the printed and written content is clearly visible for a long time. In addition, it has good tolerance to common office chemicals such as glue and ink, and will not react adversely with these chemicals to affect the quality and performance of the paper.

Optical properties: The whiteness of offset paper is usually between 85% and 90%, with high brightness and good color reproduction. Its surface smoothness is high, generally between 100-200 seconds (according to the Buick smoothness test standard), which can make the printing ink or writing handwriting evenly adhere to the paper surface, presenting clear and sharp text and images with good visual effects. In addition, its opacity is also high, generally above 90%, which can effectively prevent the mutual penetration of the printed content on the front and the content on the back, ensuring the clarity and beauty of the printed matter.

Printing performance: The ink absorption of offset paper is moderate, generally between 1.5-2.5 grams/square meter, and can quickly and evenly absorb the printing ink, so that the ink dries quickly on the paper surface, and there will be no penetration, paper bleeding and other phenomena, ensuring the printing quality. It has good printability and can adapt to various printing methods, such as offset printing, gravure printing, etc., and it is not easy to produce powder loss and hair loss during the printing process, which can ensure the normal operation and printing efficiency of the printing equipment.

Dimensional stability: The size of offset paper changes little under different environmental conditions. In an environment with a relative humidity of 40%-60% and a temperature of 20-25 degrees Celsius, its longitudinal expansion rate is generally between 0.1%-0.2%, and its transverse expansion rate is generally between 0.2%-0.3%, which can ensure the dimensional accuracy of printed and written products, and will not affect the layout and overall effect of the content due to the expansion and contraction of the paper.

Application:

Printing industry: In the field of magazine printing, Double Offset Paper can present exquisite pictures and clear text, bringing a good visual experience to readers, and is suitable for the printing of various fashion magazines, cultural magazines, academic magazines, etc. For book printing, whether it is novels, textbooks, picture albums or reference books, offset paper can meet its requirements for paper quality and printing effects, and ensure the printing quality and service life of books. In brochure printing, the company's product brochures, service brochures, etc. are usually printed on offset paper to show the corporate image and product features and attract customer attention.

Office field: Offset paper is one of the indispensable paper materials in daily office work, such as for printing documents, reports, contracts, letters, etc. Its good flatness and printing adaptability can ensure the clarity and neatness of document printing, improve office efficiency and document readability. In addition, offset paper can also be used to make office forms, labels, etc., which is convenient for information recording and management.

Education field: In the printing of textbooks, offset paper can withstand students' frequent flipping and use, ensure the integrity and durability of textbooks, and provide students with good learning materials. For exercise book printing, the smooth surface of offset paper is convenient for students to write, and the ink is not easy to penetrate, which can ensure the clarity and neatness of writing, and help students improve their learning effects. At the same time, offset paper can also be used to make teaching courseware, teaching materials, etc. to provide support for teaching activities.

Commercial field: offset paper is widely used in the printing of commercial bills, such as invoices, receipts, checks, etc. Its security and stability can ensure the authenticity and integrity of bill information, prevent information tampering and loss, and provide reliable vouchers for commercial transactions. In terms of product packaging, offset paper can be used to make product manuals, packaging boxes, etc., which can protect products and provide product information, enhance the brand image and market competitiveness of products.

Art field: For the creation and display of artworks, such as sketches, watercolors, prints, etc., offset paper can provide a good painting foundation. Its delicate texture and moderate water absorption can make the painting pigments evenly adhere to the paper surface, presenting rich colors and delicate brushstrokes, providing artists with a broad creative space to achieve various artistic styles and forms of expression.

Maintenance Tips:

Storage environment: Double Offset Paper should be stored in a dry, ventilated, clean environment, avoiding direct sunlight and high temperature and humidity. The temperature of the warehouse should be controlled between 20-25 degrees Celsius, and the relative humidity should be maintained between 40%-60% to prevent the paper from getting damp, moldy or deformed. At the same time, the paper should be placed on a flat shelf to avoid long-term stacking or heavy pressure to prevent the paper from wrinkling or damage.

Cleaning and maintenance: During use, the surface of the offset paper should be kept clean to avoid dust, oil and other impurities on the surface of the paper. If there are stains on the surface of the paper, wipe it gently with a clean soft cloth, but be careful not to use too much force to avoid damaging the surface of the paper. For printed offset paper, avoid touching the printed surface to prevent fingerprints or other stains from affecting the printing effect.

Moisture and mildew proof: In order to prevent the offset paper from getting damp and moldy, desiccant, such as silica gel desiccant or lime desiccant, can be placed in the storage environment, and the desiccant should be replaced regularly to keep the environment dry. In addition, you can also use mildewproof agents to treat the paper, but be careful to choose the right mildewproof agent to avoid adverse effects on paper quality and human health.

Arrangement and storage: During use, the paper should be sorted and arranged according to its specifications and uses for easy access and management. For unused offset paper, the packaging should be kept intact to prevent the paper from being directly exposed to the air and getting damp. If the paper has been opened but not used up, it should be resealed to prevent the edge of the paper from absorbing moisture or being contaminated.

Temperature and humidity control: In places where offset paper is used and stored, temperature and humidity adjustment equipment such as air conditioners and dehumidifiers should be equipped to monitor and control the temperature and humidity of the environment in real time. Especially in the rainy season or humid areas, more attention should be paid to strengthening moisture-proof measures to ensure the stable quality of offset paper. At the same time, avoid mixing offset paper with other volatile and corrosive items to avoid damage to the paper.