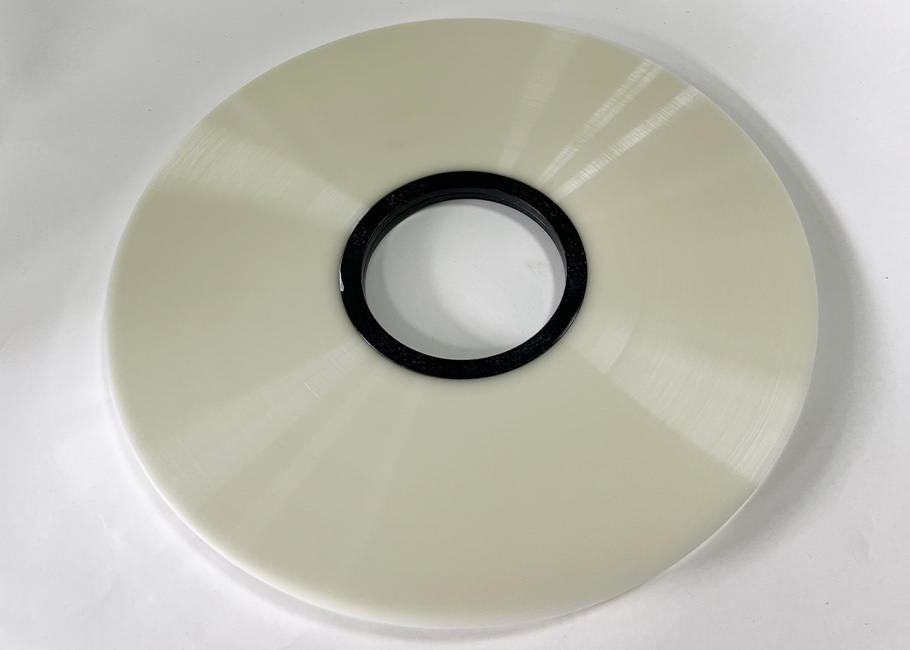

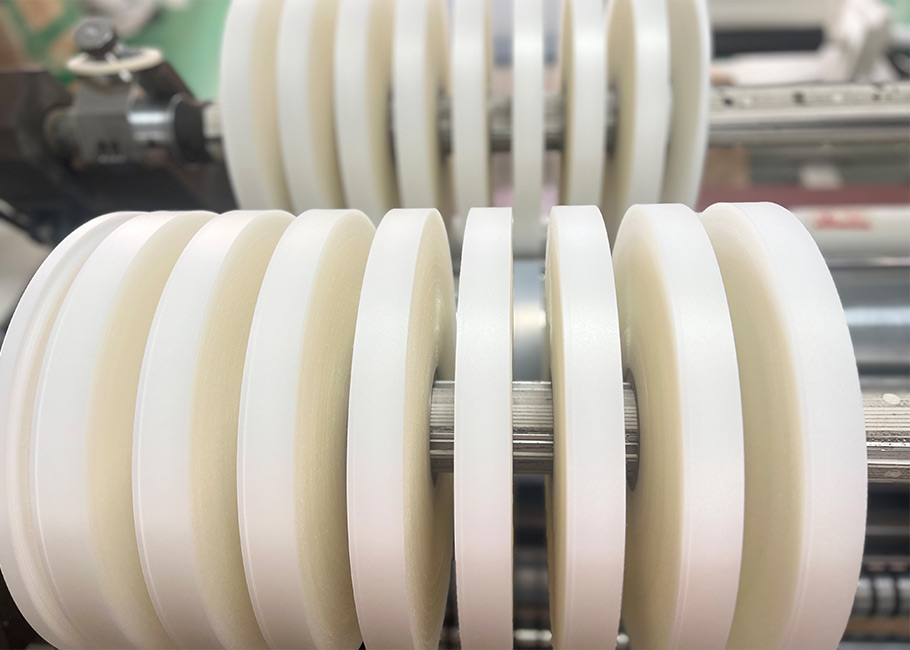

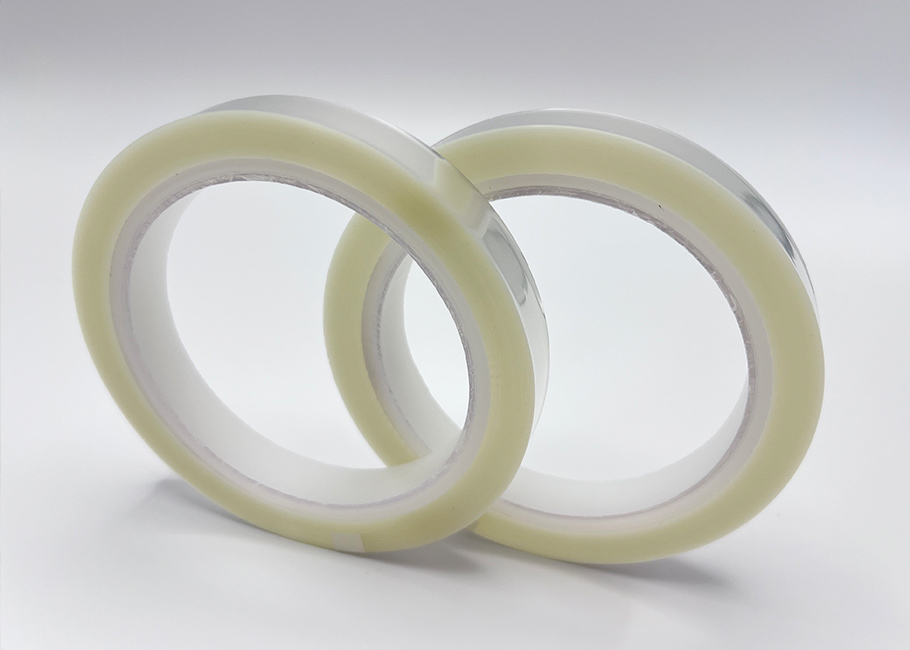

Clear Polyester Film Roll

- Product Information

Clear Polyester Film is a high-performance film material made of polyethylene terephthalate (PET) through extrusion, stretching and other processes. It is milky white or light yellow, has a highly crystalline structure, and a smooth and shiny surface. This film has a wide range of applications in many fields due to its unique molecular structure and physical properties.

Clear Polyester Film Parameters:

| Material: | PET |

| Dimensions: | Customizable Material Width And Thickness According To Customer Requirements |

| OEM: | OEM/ODM Available |

| Packaging: | Carton |

Clear Polyester Film Features:

Material: PET: Clear Polyester Film is based on polyethylene terephthalate (PET). This high molecular polymer has excellent comprehensive properties and is one of the most important varieties of thermoplastic polyester.

Good tensile strength: It has high tensile strength and can withstand large tensile forces without breaking easily, which enables it to effectively protect products in packaging, electronics and other fields to prevent damage due to external forces during transportation and use.

Good performance: Clear Polyester Film performs well in mechanical, chemical and electrical properties. It has high mechanical strength and good wear resistance, and can resist friction and wear in daily use; it has strong chemical stability, has good tolerance to most chemicals, and is not prone to chemical reactions; it has excellent electrical insulation properties, and can maintain stable insulation effects even in harsh environments such as high temperature and high humidity, and is suitable for the manufacture of electronic and electrical products.

Strong stability: The film has good dimensional stability, and its dimensional changes are minimal under different temperature and humidity conditions, which can ensure the accuracy and consistency of the product. At the same time, it also has excellent weather resistance. It will not age, discolor or deteriorate due to natural factors such as ultraviolet rays, wind and rain when exposed to outdoor environment for a long time.

High transparency and good gloss: Clear Polyester Film has high transparency and good light transmittance, which can clearly show the appearance of the product and enhance the visual appeal of the product. Its surface is smooth and glossy, giving the product a high-end and exquisite texture and enhancing the market competitiveness of the product.

Excellent barrier performance: It has a good barrier effect on gas, water vapor, grease, etc., can effectively prevent the intrusion of external substances, maintain the purity and stability of the product, extend the shelf life of the product, and provide users with a longer use cycle and higher economic benefits.

Good temperature resistance: Clear Polyester Film can be used for a long time in a wide temperature range, with strong heat resistance and cold resistance. It will not deform, soften or embrittle due to temperature changes, ensuring the stability and reliability of the product in different environments.

Environmentally friendly and recyclable: As a recyclable material, Clear Polyester Film conforms to modern environmental protection concepts. After being discarded, it can be recycled and reused through physical or chemical methods, reducing pollution to the environment, realizing the recycling of resources, and bringing environmental benefits to users.

Clear Polyester Film Application:

Packaging field: Clear Polyester Film is widely used in the packaging of food, medicine, cosmetics and other products. It can be made into various packaging bags, labels, films, etc., which can not only effectively protect the products and prevent the influence of external factors, but also improve the beauty and attractiveness of the packaging through printing, lamination and other processes, and enhance the market competitiveness of the products. In addition, its good barrier properties and temperature resistance make it suitable for various packaging forms such as vacuum packaging and inflatable packaging to meet the packaging needs of different products.

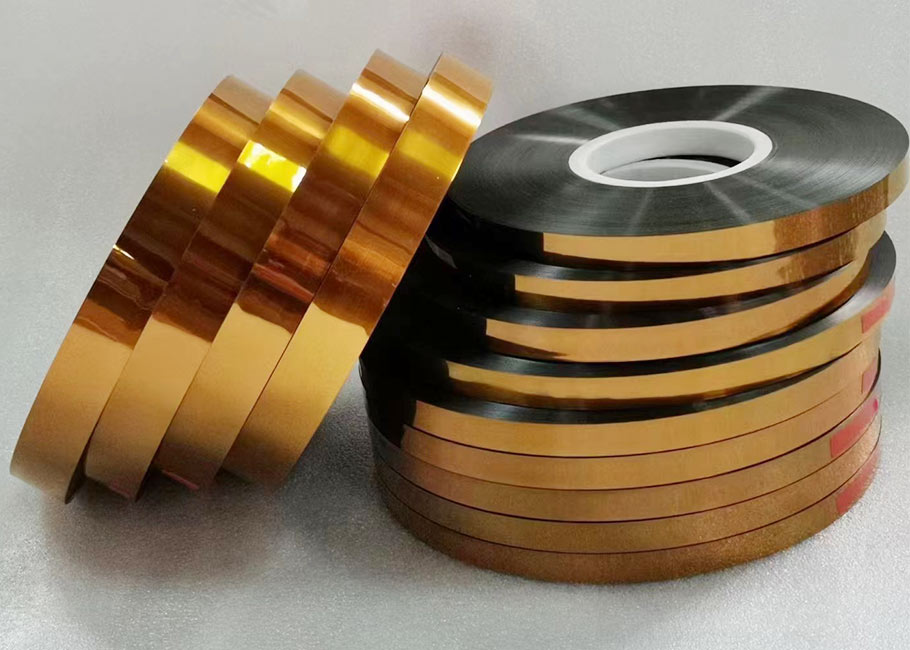

Electronic field: In the electronic and electrical industry, Clear Polyester Film is an important material for manufacturing various electronic components and parts. For example, it is used to produce insulating films, bobbins, coils, etc. in equipment such as capacitors, transformers, and motors, which can provide good electrical insulation and mechanical strength to ensure the normal operation and service life of electronic equipment. At the same time, it can also be used to manufacture protective films for products such as electronic displays and touch screens to prevent screen scratches and damage, and improve the product's user experience and reliability.

Automobile field: Clear Polyester Film also has important applications in automobile manufacturing. It can be used to make protective films for automotive interior parts, such as decorative films for dashboards, center consoles, seats, etc., which can prevent interior parts from being worn, scratched and stained during use, and keep the interior clean and beautiful. In addition, it can also be used for thermal insulation films and explosion-proof films for car windows, etc., to improve the thermal insulation performance and safety of windows, and provide a comfortable driving environment for drivers and passengers.

Industrial field: In the fields of machinery manufacturing, chemical industry and other industries, Clear Polyester Film can be used to manufacture various industrial films, filter membranes, conveyor belts, etc. For example, in chemical production, it can be used as a filter medium to separate impurities in liquids or gases, improve production efficiency and product quality. In machinery manufacturing, it can be used to manufacture the surface coating of conveyor belts, improve the wear resistance and corrosion resistance of conveyor belts, and extend their service life.

Construction field: Clear Polyester Film also has certain applications in the construction industry, such as thermal insulation films and UV protection films for building doors and windows, which can effectively reduce the energy consumption of buildings and improve indoor comfort and energy saving effects. In addition, it can also be used as a surface protective film for building decoration materials, such as tiles, stones, etc., to prevent the decorative materials from being damaged and contaminated during construction and use, and maintain their beauty and durability.

Clear Polyester Film Maintenance:

Cleaning and maintenance:

Use a soft dry cloth to gently wipe the surface of Clear Polyester Film regularly to remove dust and stains. Avoid using rough cleaning tools or detergents containing granular substances to avoid scratching the surface of the film and affecting its gloss and transparency.

For stubborn stains, first dilute with an appropriate amount of neutral detergent and gently wipe it, then wipe it clean with clean water, and finally wipe it dry with a dry cloth to avoid moisture residue causing the film to become damp or breed bacteria.

Storage environment:

When storing Clear Polyester Film, choose a dry, ventilated, and cool environment to avoid direct sunlight and high temperature environment to prevent the film from aging, discoloration, or performance degradation. It is recommended to store the film on indoor shelves to avoid direct contact with the ground to prevent moisture and contamination.

During storage, the film roll or sheet should be placed flat to avoid folding or bending for a long time to avoid permanent deformation and affect its performance. If long-term storage is required, it is recommended to check the state of the film regularly to ensure that it is not damaged.

Environmental control:

In the environment where Clear Polyester Film is used, the temperature and humidity should be kept stable as much as possible, and drastic temperature changes and excessively high or low humidity conditions should be avoided to ensure the stable performance of the film. For example, in electronic equipment manufacturing workshops or food packaging workshops, environmental conditions can be controlled by air conditioning systems and dehumidification equipment.

Avoid exposing the film to corrosive environments such as strong acids, strong alkalis, and organic solvents for a long time. If it is necessary to use it in a special chemical environment, compatibility testing should be carried out in advance to ensure that the film will not react adversely with chemicals and affect its performance and safety.

Mechanical protection:

When transporting and installing Clear Polyester Film, it should be handled with care to avoid severe collisions, squeezing or stretching to avoid damage to the film, deformation, or damage to the internal structure. For larger film products, it is recommended to use appropriate handling tools and equipment, such as forklifts, cranes, etc., to ensure the safety and stability of the operation.

During use, the film should be avoided from contact with sharp objects to prevent scratches or punctures. For example, when using the protective film for car interiors, care should be taken to avoid friction between sharp objects such as keys and coins and the film surface to maintain the integrity and aesthetics of the film.

Regular inspection and maintenance:

Regularly inspect the Clear Polyester Film in use to observe whether there are scratches, cracks, discoloration and other abnormal phenomena on its surface, as well as whether there is a decline in performance, such as reduced transparency and weakened barrier properties. Once a problem is found, appropriate repair or replacement measures should be taken in time to ensure the normal use of the film and the quality of the product.

For some special film applications, such as insulating films in electronic equipment and thermal insulation films for building doors and windows, it is recommended to perform professional maintenance and inspection regularly according to the maintenance plan of the equipment or building to extend the service life of the film and ensure the effectiveness of its functions.